Salford

Salford Valmar AirFlo 8600 Pull-Type Fertilizer Spreader

|

Features |

Delivering Greater Capacity and Flexibility in a Commercial Pull-Type Spreader

Cover More Acres in Less Time

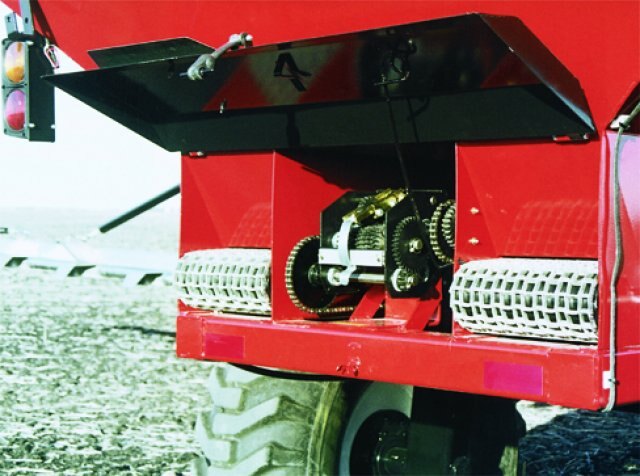

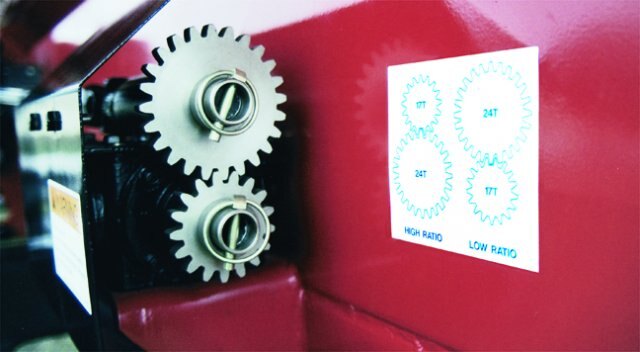

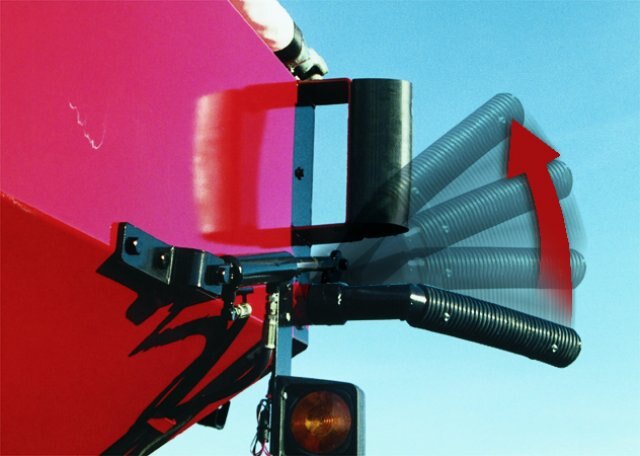

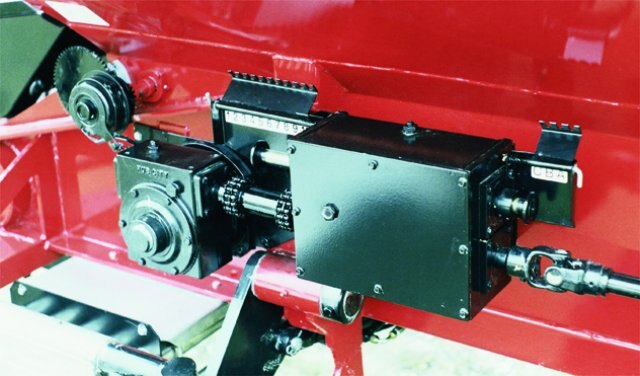

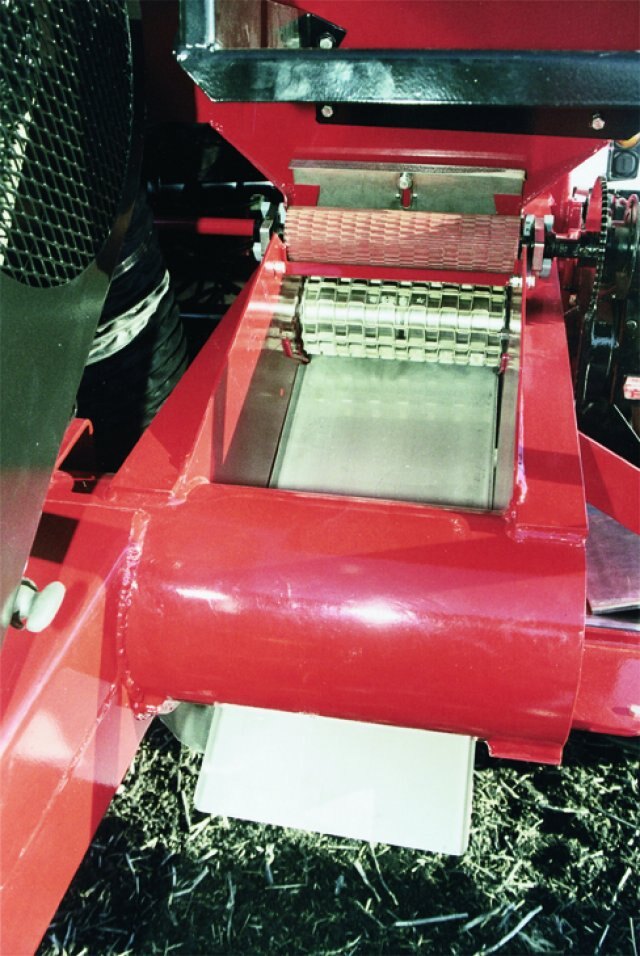

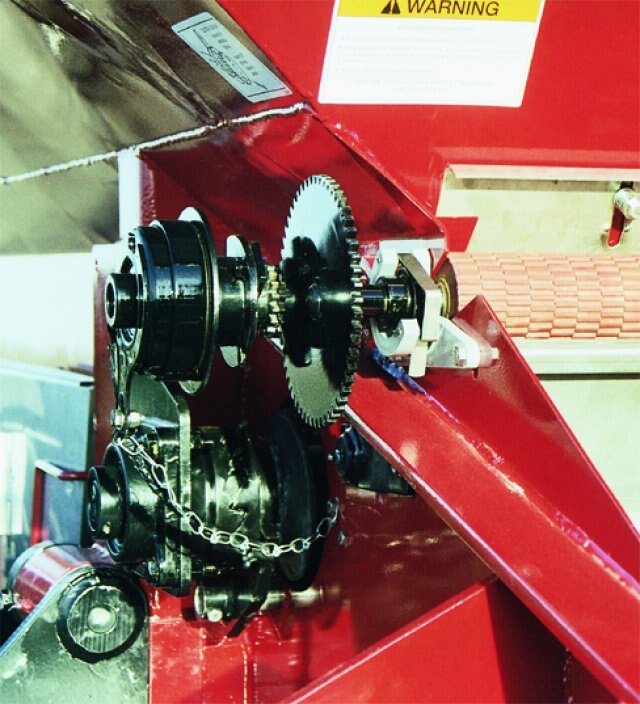

Accurate Metering System The Airflo 8600 precise rate is a result of the ground-driven metering system that automatically adjusts on the go to ensure a uniform application rate regardless of ground speed. The hydraulically engaged metering system is based on a 30-setting, oil bath gearbox combined with a two-speed gear ratio to allow 60 settings that can be adjusted in increments of seven percent. This enables operators to select from more settings at closer increments, a feature that translates into more control over application rate for substantial savings in fertilizer costs. The 8600 can also be equipped with a hydraulic drive metering system for those using variable rate technology. Spread More Product between Fills The 8600’s extra-large, 230-cubic-foot hopper can carry up to seven tons of product. With a capacity like that, you’ll be able to cover more acres between fills. The hopper itself is constructed of corrosion-resistant, painted 409 stainless steel and comes with a roll tarp installed. Ideal for Row Crop Farming Originally designed to meet the needs of row crop farmers, the 8600 features axles which can be adjusted from 72 inches to 120 inches to accommodate most row spacings. In addition, the 8600 can be equipped with optional tire sizes to achieve greater flotation or narrower tracking, depending on the operation. High Capacity PTO or Hydraulic Driven Fan This fan has field-proven history on the Air Max. With an operating speed of 4,700 RPM, the fan’s air flow feeds through a nine-inch outlet directly to a two-piece manifold. Important features include a 17-inch fan impeller with plastic impeller blades and a four-band fan belt with tightener. The standard fan drive is a 1,000 RPM, 1 3/8-inch, 21T spline drive shaft. An optional 20T, 1 3/4-inch yoke with bridge is available for those requiring a larger driveline. Valmar also offers an optional hydraulic driven fan drive. This option requires 35 gallons per minute hydraulic flow operating at 2225 PSI – well within the capability of some of today’s higher capacity tractors. Durable and Easy to Maintain The 8600 includes a number of important features that provide for increased durability and easier maintenance. For long life, the hopper and booms are manufactured from stainless steel. There is easy access to all mechanical parts including the manifold. Finally, calibration and emptying of the unit is easier, thanks to funnel trays that are inserted under the metering system for easy collection of material. Choose Boom Width to Match Your Needs The Valmar 8600 comes with a standard 66-foot boom but can also be equipped with optional boom widths of 60 feet, 54 feet or 57 feet, allowing you to match boom width to your crop requirements. Booms are hydraulically folded and feature a hydraulic shut-off on the right boom to allow application on the left side only. All booms are equipped with rubber torsion boom suspension (which do not require any service and reduce friction, bouncing, and wear) and manual folding, break-away tips to minimize damage that may occur from striking obstacles in the field. Easy to Operate Designed for easy use, all important field operations on the Valmar 8600 are hydraulically controlled from the cab through the use of three separate hydraulic lines (four lines with optional hydraulic fan drive). For example, the booms are folded, unfolded and locked hydraulically (through the use of a sequencer valve), allowing quick and easy transition to and from transport position. Also, the metering drive wheel is engaged or disengaged hydraulically and comes equipped with a lockout valve to ensure ongoing positive engagement. Finally, half width application is possible thanks to a hydraulically operated half shut-off clutch system that comes equipped with a pressure relief valve for trouble free operation. |

|

Specifications |

|

Hopper:

Booms:

Metering:

Fan:

Hydraulics:

Chassis:

Second Metering System:

Dimensions/Shipping Information:

|